Ensuring the Longevity of Your Dryer Duct System: Maintenance Cleaning vs. Restorative Cleaning

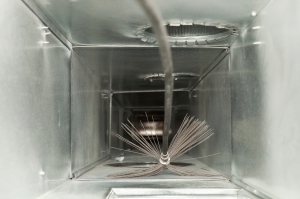

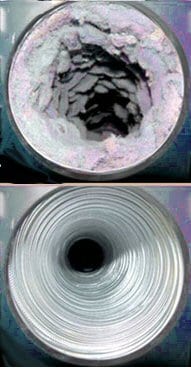

Regular cleaning is essential for maintaining the safety and efficiency of a home’s dryer system. Dryer duct cleaning is extremely important since this critical maintenance task prevents potential problems such as fire and water damage.

Despite what most people think, the most common damage resulting from improperly maintained dryer ducts is moisture damage, not fire. This is because, when a blockage occurs condensation forms and collects within the pipe. Over time, this moisture can find its way into the structure causing thousands of dollars of damage to the building.

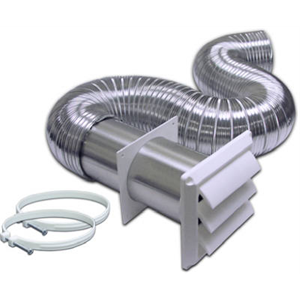

their construction and designs. Dryer vents are no exception. The image most people have of dryer vents are round three to four inches in diameter circular metal pipe with a flap on the end. While this is a common (if not the most common) design, especially for low-rise buildings, there are a number of different configurations that are employed.

their construction and designs. Dryer vents are no exception. The image most people have of dryer vents are round three to four inches in diameter circular metal pipe with a flap on the end. While this is a common (if not the most common) design, especially for low-rise buildings, there are a number of different configurations that are employed. , if it is even an option, can run into the tens of thousands of dollars. The alternative is to build a new duct run with a drop down ceiling. While less costly than concrete reconstruction, it can be aesthetically ugly and diminish a unit’s value.

, if it is even an option, can run into the tens of thousands of dollars. The alternative is to build a new duct run with a drop down ceiling. While less costly than concrete reconstruction, it can be aesthetically ugly and diminish a unit’s value.